Difference between revisions of "HFI cryogenics"

(→Dilution) |

(→Dilution) |

||

| Line 15: | Line 15: | ||

The dilution was operated with flows set to the minimum available values, and provided a total | The dilution was operated with flows set to the minimum available values, and provided a total | ||

lifetime of 30.5 months, exceeding the nominal lifetime of 16 months by 14.5 months. The | lifetime of 30.5 months, exceeding the nominal lifetime of 16 months by 14.5 months. The | ||

| − | dilution stage was stabilized by | + | dilution stage was stabilized by PID1 using a power of 20 to 30nW |

providing a temperature close to 101mK. The bolometer plate was stabilized by PID2 at 102.8mK with about 5nW. The cooling power values were in very good agreement with those obtained during the ground tests and calibration. | providing a temperature close to 101mK. The bolometer plate was stabilized by PID2 at 102.8mK with about 5nW. The cooling power values were in very good agreement with those obtained during the ground tests and calibration. | ||

| − | However, the cosmic particles interactions with the | + | However, the cosmic particles interactions with the 0.1K stages induced both temperature fluctuations of the 0.1K plates and glitches on the thermometers measurements. |

The baseline correction of the bolometers signals from the 100mK bolometer stage temperatures fluctuations is described in the [[TOI processing]] section. | The baseline correction of the bolometers signals from the 100mK bolometer stage temperatures fluctuations is described in the [[TOI processing]] section. | ||

Revision as of 14:41, 13 February 2013

Cryogenics[edit]

(F .Pajot)

Dilution[edit]

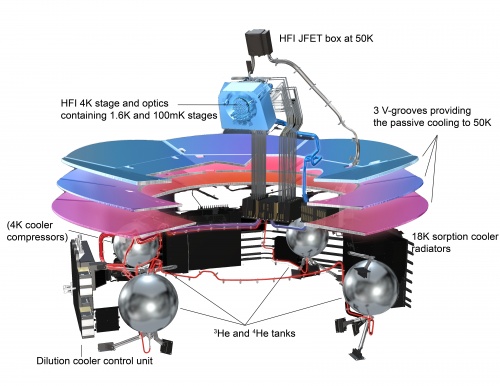

The HFI dilution cooler produces temperatures of 0.1K for the bolometers through the dilution of 3He into 4He and 1.4K through Joule-Thomson expansion of the 3He and 4He mixture. Two stages of PID regulation are included on the 0.1K stage. The first one (PID1) is at the dilution cold end itself and provides stability on long timescales. When no thermal perturbation is applied to the bolometer plate, PID1 alone provides the required stability. A passive thermal filter is mounted between the dilution cold end and the bolometer optical plate. It gives a thermal time constant of several hours between these stages. A second regulation system (PID2) is on the bolometer plate, with a similar time constant. The dilution cooler is described in detail in section 2.3.3 of Planck early paper II .

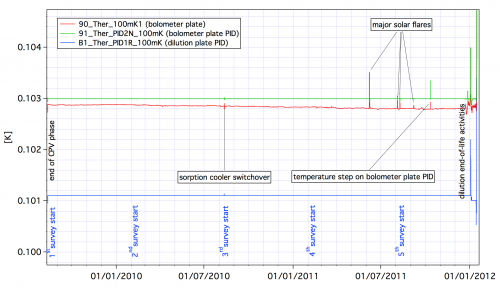

The dilution was operated with flows set to the minimum available values, and provided a total lifetime of 30.5 months, exceeding the nominal lifetime of 16 months by 14.5 months. The dilution stage was stabilized by PID1 using a power of 20 to 30nW providing a temperature close to 101mK. The bolometer plate was stabilized by PID2 at 102.8mK with about 5nW. The cooling power values were in very good agreement with those obtained during the ground tests and calibration. However, the cosmic particles interactions with the 0.1K stages induced both temperature fluctuations of the 0.1K plates and glitches on the thermometers measurements. The baseline correction of the bolometers signals from the 100mK bolometer stage temperatures fluctuations is described in the TOI processing section.

At very low frequency, below 1mHz, the temperature fluctuations are very well correlated with the high energy particles hit rate, as measured by the on-board monitor. At frequencies in the 10mHz to 1Hz range, single events inducing a global or partial temperature change of the bolometer plate are observed.

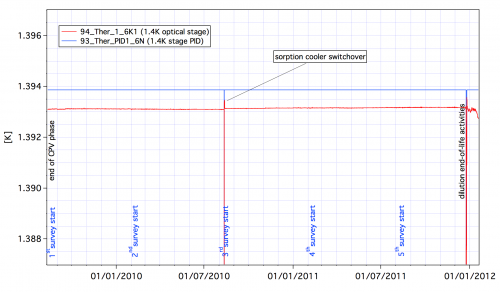

The 1.4K stage is very stable and given the very low coupling coefficients between the 1.4K optical components and the detectors no effect can be measured on the signal.

Detailed thermal analysis of the in-flight stability of the dilution cooler can be found in section 5.4 of Planck early paper II .

4K J-T cooler[edit]

The HFI 4K J-T cooler produces a temperature of 4K for the HFI 4K stage and optics and the precooling of the dilution gases. Full description of the 4K cooler can be found in in section 2.3.2 of Planck early paper II .

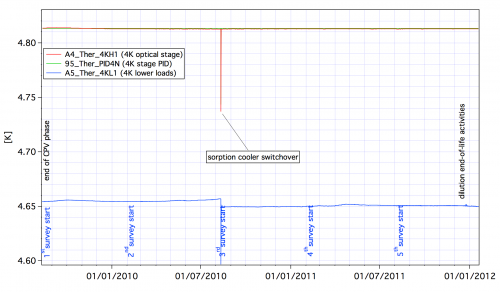

The two mechanical compressors produce micro-vibrations and also induce electromagnetic interference affecting the science signals of bolometers. The risks associated with these effects were taken into account early in the design of the HFI by phase-locking the sample frequency of the data to a harmonic of the compressors frequency. Operation of the 4K cooler was flawless during the whole mission, but for an unexpected shutdown on August 6th 2009, caused by an SEU on the precharge regulator, that never occured again.

It was operated without interruption during all the survey phase of the mission. It is still in operation as it also provides the cooling of the optical reference loads of the LFI. The 4K PID stabilizing the temperature of the HFI optics is regulated at 4.81 K using a power around 1.8 mW.

The 4K J-T cooler compressors amplitude was set to 3450 micrometers during the CPV, and was maintained to this value during all the mission. Its cooling power is very stable and gives enough margin to cancel out the fluctuations induced by the sorption cooler fluctuations and adjustments. Following the unexpected shutdown of the compressors during CPV, their operation was nominal during all the rest of the mission.

Details on the in-flight performance of the 4K J-T cooler can be found in in section 5.3 of Planck early paper II .

(Planck) High Frequency Instrument

[LFI meaning]: absolute calibration refers to the 0th order calibration for each channel, 1 single number, while the relative calibration refers to the component of the calibration that varies pointing period by pointing period.

(Planck) Low Frequency Instrument

Calibration and Performance Verification