Difference between revisions of "LFIAppendix"

(Created page with 'This is the LFI Appendix') |

|||

| Line 1: | Line 1: | ||

| − | This is the LFI | + | === Appendix: LFI Instrument === |

| + | |||

| + | ==== ''Feed Horns (FH)''==== | ||

| + | |||

| + | Dual profiled corrugated horns have been selected at all LFI frequencies as the best design in terms of shape of the main lobe, level of the side lobes, control of the phase centre, and compactness. Dual profiled LFI horns are composed by a Sine Squared profiled section, and an exponential profile near the aperture plane. | ||

| + | In order to optimise the optical matching of the feeds phase centres to the telescope focal surface, while preventing obscuration between horns, LFI has 6 different feed horn designs. For each frequency, the number of feeds and the number of different designs are reported in Table 1 below. | ||

| + | |||

| + | {| border="1" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 1. Number of LFI feed horns and number of different feed horn designs''' | ||

| + | |- | ||

| + | !scope="col"| Frequency (GHz) | ||

| + | !scope="col"| Number of Horns | ||

| + | !scope="col"| Number of designs | ||

| + | |- | ||

| + | |width="150" |30 | ||

| + | |width="120" |2 | ||

| + | |width="120" |1 | ||

| + | |- | ||

| + | |width="150" |44 | ||

| + | |width="120" |3 | ||

| + | |width="120" |2 | ||

| + | |- | ||

| + | |width="150" |70 | ||

| + | |width="120" |6 | ||

| + | |width="120" |3 | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

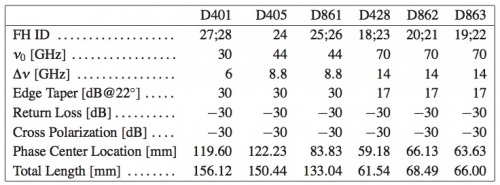

| + | LFI feed horn design specifications are reported in the table 2 below. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 2. LFI feed horn design specifications. The edge taper is the taper used to optimize the optical response; the return loss and the cross polarization are the maximum design values over the whole bandwidth; The phase center location is defined as the distance between the horn flange and the focal surface of the telescope.''' | ||

| + | |- | ||

| + | |width="700" | [[File:fh1.jpg|thumb|center|500px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The design process led to a corrugation profile composed by a mixture of a sine-squared section, starting from the throat, and an exponential section near the aperture plane. The length of this last has a direct impact on the location of the phase center. The analytical expression of the corrugation profile, <math>R(z)</math>, is the following | ||

| + | |||

| + | <math> \label{eq:fh1} | ||

| + | R(z) = R_{th} +(R_s −R_{th}) ((1−A) \frac{z}{L_s} + A \, sin^\beta \, (\frac{\pi \, z}{2 \, L_s})) </math> | ||

| + | : <math> 0 ≤ z ≤ L_s | ||

| + | </math> | ||

| + | |||

| + | in the sine section, and | ||

| + | |||

| + | <math> \label{eq:fh2} | ||

| + | R(z)= R_s+e^{\alpha(z−L_s)}−1; \; \alpha = \frac{1}{L_e} ln(R_{ap}−R_s) </math> | ||

| + | : <math> L_s ≤ z ≤ L_e + L_s | ||

| + | </math> | ||

| + | |||

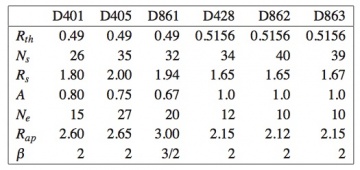

| + | in the exponential region. Here, <math>R_{th}</math> is the throat radius, <math>R_s</math> is the sine squared region end radius (or exponential region initial radius), <math>R_{ap}</math> is the aperture radius, <math>L_s</math> is the sine squared region length and <math>L_e</math> is the exponential region length. The parameter <math>A (0 ≤ A ≤ 1)</math> modulates the first region profile between linear and pure sine squared type. The parameters <math>L_e/(L_e + L_s)</math>, <math>A</math> and <math>R_s</math> can be used to control, as far as possible, the position and frequency stability of the phase center and the compactness of the structure. The feed horn parameters are reported in table 3 below. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 3. LFI feed horn parameters. <math>R_{th}</math>: Throat radius; <math>N_s</math>: Number of corrugation of the <math>sin^\beta </math> section; <math>R_s</math>: end radius of <math>sin^\beta</math> section; <math>A</math>: tapering coefficient; <math>N_e</math>: number of corrugation of the exponential section; <math>R_{ap}</math>: final aperture diameter.''' | ||

| + | |- | ||

| + | |width="500" | [[File:fh2.jpg|thumb|center|360px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The qualification campaign, mainly focused on RF return loss and pattern (amplitude and phase) measurements, was successfully concluded. The agreement between the pattern measurements and the expected performances (simulated using nominal corrugation profile) is excellent both in amplitude and in phase. Moreover reflection measurements show a good impedance match for all the horns, the return loss being better than -30 dB over the whole 20% of operational bandwidth. | ||

| + | |||

| + | Details of the design, flight model and tests of Planck-LFI feed horns can be found in <cite>#villa2009</cite>. | ||

| + | |||

| + | ==== ''OrthoMode Transducers (OMT)''==== | ||

| + | |||

| + | The Ortho–Mode Transducer (OMTs) separates the radiation collected by the feed horn in two orthogonal polarisation components. It consists of a circular to square waveguide transition (directly connected to the FH), a square waveguide section and two separate rectangular waveguide (the through and side arms, which separate and pick up the orthogonal polarisation, connected with the FEU). On the side arms is always present a 90 degrees bend, while a twist is also necessary on the main (30 and 44 GHz) and side (70GHz) arm, in order to math the FEU polarisation. | ||

| + | |||

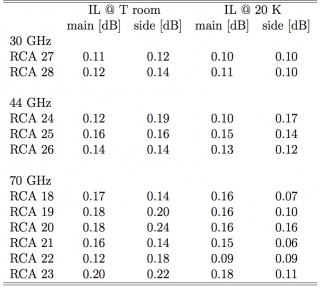

| + | The required and measured performances for the LFI OMTs at all frequencies are reported in the following tables 4 and 5: | ||

| + | |||

| + | {| border="1" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 4. Performance Characteristics of the LFI OMTs based on measurements. The values are the worst values over the entire 20% of bandwidth.''' | ||

| + | |- | ||

| + | !scope="col"| OMT ID | ||

| + | !scope="col"| Bandwidth [GHz] | ||

| + | !scope="col"| X–Pol [dB] (Main) | ||

| + | !scope="col"| X–Pol [dB] (Side) | ||

| + | !scope="col"| Return–Loss [dB] (Main) | ||

| + | !scope="col"| Return–Loss [dB] (Side) | ||

| + | |- | ||

| + | |width="80" |18 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<29 | ||

| + | |width="100" |<30 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-20.0 | ||

| + | |- | ||

| + | |width="80" |19 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<26 | ||

| + | |width="100" |<28 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-20.0 | ||

| + | |- | ||

| + | |width="80" |20 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<32 | ||

| + | |width="100" |<35 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-20.0 | ||

| + | |- | ||

| + | |width="80" |21 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<32 | ||

| + | |width="100" |<37 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-18.0 | ||

| + | |- | ||

| + | |width="80" |22 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<26 | ||

| + | |width="100" |<28 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-18.0 | ||

| + | |- | ||

| + | |width="80" |23 | ||

| + | |width="100" |14 | ||

| + | |width="100" |<26 | ||

| + | |width="100" |<28 | ||

| + | |width="100" |-15.0 | ||

| + | |width="100" |-20.0 | ||

| + | |- | ||

| + | |width="80" |24 | ||

| + | |width="100" |8.8 | ||

| + | |width="100" |<38 | ||

| + | |width="100" |<40 | ||

| + | |width="100" |-13.0 | ||

| + | |width="100" |-18.0 | ||

| + | |- | ||

| + | |width="80" |25 | ||

| + | |width="100" |8.8 | ||

| + | |width="100" |<31 | ||

| + | |width="100" |<32 | ||

| + | |width="100" |-13.0 | ||

| + | |width="100" |-18.0 | ||

| + | |- | ||

| + | |width="80" |26 | ||

| + | |width="100" |8.8 | ||

| + | |width="100" |<27 | ||

| + | |width="100" |<25 | ||

| + | |width="100" |-13.0 | ||

| + | |width="100" |-17.0 | ||

| + | |- | ||

| + | |width="80" |27 | ||

| + | |width="100" |6 | ||

| + | |width="100" |<38 | ||

| + | |width="100" |<44 | ||

| + | |width="100" |-16.0 | ||

| + | |width="100" |-23.0 | ||

| + | |- | ||

| + | |width="80" |28 | ||

| + | |width="100" |6 | ||

| + | |width="100" |<36 | ||

| + | |width="100" |<38 | ||

| + | |width="100" |-16.0 | ||

| + | |width="100" |-22.0 | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 5. Mean value of the IL over LFI bandwidth estimated at 20K and measured at room temperature.''' | ||

| + | |- | ||

| + | |width="400" | [[File:omt.jpg|thumb|center|320px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The details of the flight models and measurements of the Planck LFI ortho-mode transducers can be found in <cite>#darcangelo2009b</cite>. | ||

| + | |||

| + | ==== ''Front End Modules (FEM)''==== | ||

| + | |||

| + | Front End Modules are located in the FPU, just in cascade of the Feed Horn and the Ortho Mode Transducers. 70 GHz FEMs are mounted onto the inner wall of the mainframe (the wall facing HFI instrument) from the HFI side. 44 and 30 GHz FEMs are inserted into the mainframe from the WG side and fixed to the bottom plate. Screws to bottom plate are inserted from WG side. | ||

| + | The LFI FEMs are the first active stage of amplification of the radiometer chain. Each FEM contains four amplification paths. Each path is composed by several cascaded LNAs followed by a phase switch. Two passive hybrids, at the input and output of the FEM, are used to mix couples of signals of the same radiometer (see Figure 4). This makes the instabilities of each chain to be applied to both the sky and load signals. | ||

| + | |||

| + | The passive hybrid coupler (magic-tee) combines the signals from the sky and cold load with a fixed phase offset of either 90 deg or 180 deg between them. It has a 20% bandwidth, low loss, and amplitude balance needed at the output to ensure adequate signal isolation. | ||

| + | |||

| + | The FEM LNAs (InP MMIC) are biased providing 1 drain line per channel (that is 4 per FEM) and 2 gate lines per channel (that is 8 per FEM). The FEM Phase switches are biased providing 2 lines per channel (that is 8 per FEM) each capable of providing a direct bias current or a reverse bias voltage. | ||

| + | |||

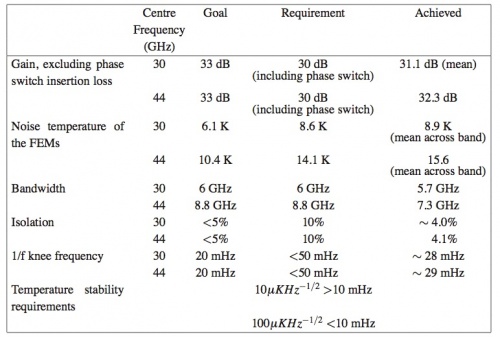

| + | The LFI FEM parameters necessary to meet the science objectives at 30 and 44 GHz were given as requirements and goals and are summarised in table 6 below where they are compared with the values actually achieved. The FEM units meet the requirements, within the measurement errors, for most parameters and in particular the noise temperature. The units come close to the more stringent goals in several parameters. Of particular note are the noise temperatures achieved; these along with the wide bandwidths are critical for the high sensitivity required for the Planck mission. Some LNAs within the FEMs met the goals at 30 GHz and 44 GHz within the measurements errors and reached 3 and 5 times the theoretical quantum limit respectively at the band centres. Furthermore, a range of tests showed that LNAs and FEMs achieved the stability levels required to meet the observing strategy of Planck. In particular, the 1/f noise knee frequency ≤29 mHz, close to the goal, met the conditions imposed by the 60 second rotation period of the spacecraft. | ||

| + | The linear polarization performance of the FEMs exceeded the requirements of the mission. The isolation between the E- and H- polarizations was measured to be between 51 and 58 dBs for the various FEMs. The LFI radiometers have very well determined position angle precision, being determined by the accuracy of the waveguide engineering. The 30 and 44 GHz geometry is accurate to ∼ <math>0.1^\circ \, </math> ; the corresponding precision is ∼ <math>1^\circ \, </math> in the HFI polarimeters. The temperature stability requirement values are also given in the table 6 below. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 6. Summary of the FEM goals, requirements and mean achieved performances.''' | ||

| + | |- | ||

| + | |width="300" | [[File:fem1.jpg|thumb|center|500px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The details of the design, development and verification of the 30 and 44 GHz front-end modules for the Planck Low Frequency Instrument can be found in <cite>#davis2009</cite>. | ||

| + | |||

| + | For what regards the 70 GHz channels, for the LNA selection of the FEMs, nine different wafers from various processing runs were evaluated, only the LNAs with the best performance were assembled as the first stage amplifiers in the FEM ACAs. For the phase switch selection, four different wafers were evaluated. When the signal is passed to an output, the gain is 35 dB or higher for almost the entire required range, and on average, the Planck requirement was fulfilled. In all FEMs, the average channel gains ranged from 34.0-40.0 dB (uncertainty ±0.1 dB). When the signal is isolated from an output, the gain is 20 dB lower or more at all frequencies. This difference in gain is used as the measure for isolation. In all the six FEMs, the channel isolation values ranged from 11.3-22.1 dB (uncertainty ±0.1 dB). | ||

| + | |||

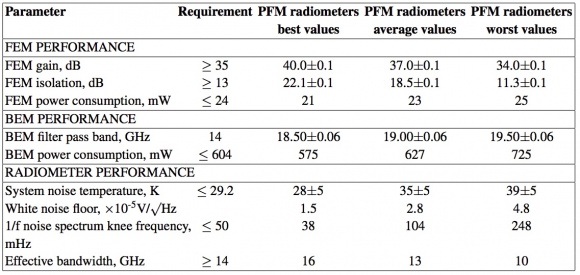

| + | Table 7 below summarises the best, the worst and the average values of the key performance parameters. The shown uncertainties are based on worst case estimates. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 7. Summary of the 70 GHz Protoflight Model radiometer performance.''' | ||

| + | |- | ||

| + | |width="300" | [[File:fembem70.jpg|thumb|center|580px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The details of the design, development and verification of the 70 GHz front-end modules for the Planck Low Frequency Instrument can be found in <cite>#varis2009</cite>. | ||

| + | |||

| + | ==== ''Waveguides''==== | ||

| + | |||

| + | The LFI Front End Unit (FEU) is connected to the Back End Unit (BEU) by 44 rectangular waveguides approximately 1.5-2.0 meter long. Each waveguide exhibits low VSWR, low thermal conductivity, low insertion loss, and low mass. In addition, the waveguide path shall permit the LFI/HFI integration and the electrical bonding between FPU and BEU. Because of the Focal Plane Unit arrangement, the waveguides are in general twisted and bended in different planes and with different angles, depending on the particular waveguide. From the thermal point of view the waveguides have to connect 2 systems (BEM and FEM) that are at very different temperatures. At BEM level the waveguides are at a temperature of 300K while at FEM level the temperature is 20K. The waveguides have to reduce the thermal flow from 300K to 20K. In Figure 1 (left panel) a conceptual sketch of the LFI configuration is shown. | ||

| + | |||

| + | All the required characteristics cannot be realized with single material waveguide configuration; a composite waveguide configuration is needed. The WGs can be considered divided in three sections: 1. 400 mm of Stainless Steel (gold plated) straight waveguide section, attached to the BEU, ending after the 3rd V–groove; | ||

| + | 2. 300 mm of non–plated Stainless Steel (SS). The SS-sections are identical for all the channels except for internal dimensions, depending on frequency. These guides are connected to all the V-grooves in order to dissipate the heat produced at BEU level. | ||

| + | 3. bended and twisted 400 microns thin electroformed copper waveguide starting at the end of the SS–section and attached to the FEU, whose length varying from around 800 mm to 1300 mm, with 2 to 4 Cu-joints. The copper waveguides section is connected to a mechanical support structure in five points in order to increase the stiffness of the waveguide. | ||

| + | |||

| + | The performance for the LFI waveguides at all frequencies are reported in the following table 8: | ||

| + | |||

| + | {| border="1" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 8. Number of LFI waveguides and performances. The Insertion Loss (IL), Return Loss (RL) and Electrical Resistance (R) values are the requirements. In between parenthesis the goal is reported also. Note that the RL value includes possible degradation due to presence of flanges.''' | ||

| + | |- | ||

| + | !scope="col"| Frequency | ||

| + | !scope="col"| <math> \nu </math> band [GHz] | ||

| + | !scope="col"| Number | ||

| + | !scope="col"| IL [dB] @20 K | ||

| + | !scope="col"| RL [dB] | ||

| + | !scope="col"| Isolation [dB] | ||

| + | !scope="col"| R [mΩ] @20 K | ||

| + | !scope="col"| R [mΩ] @300 K | ||

| + | |- | ||

| + | |width="80" | 30 | ||

| + | |width="100" | 27-33 | ||

| + | |width="100" |8 | ||

| + | |width="100" |<2.5 (1.0) | ||

| + | |width="100" |<-25 | ||

| + | |width="100" |<-30 | ||

| + | |width="100" |11.8 | ||

| + | |width="100" |27.3 | ||

| + | |- | ||

| + | |width="80" | 44 | ||

| + | |width="100" | 39.6-48.4 | ||

| + | |width="100" |12 | ||

| + | |width="100" |<3.0 (1.5) | ||

| + | |width="100" |<-25 | ||

| + | |width="100" |<-30 | ||

| + | |width="100" |14.7 | ||

| + | |width="100" |34.1 | ||

| + | |- | ||

| + | |width="80" | 70 | ||

| + | |width="100" | 63-77 | ||

| + | |width="100" |24 | ||

| + | |width="100" |<5.0 (3.5) | ||

| + | |width="100" |<-25 | ||

| + | |width="100" |<-30 | ||

| + | |width="100" |26.2 | ||

| + | |width="100" |60.5 | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | From the thermal point of view the waveguides have to connect 2 systems (BEM and FEM) that are at different temperatures. At BEM level the waveguides are at a temperature of 300K while at FEM level the temperature is 20K. Along the Stainless Steel section the waveguides have to reduce the thermal flow from 300K to 20K. The Stainless Steel waveguide is connected to all the V-grooves in order to dissipate the heat produced at BEU level. | ||

| + | |||

| + | Details of the Planck-LFI flight model of the composite waveguides can be found in <cite>#darcangelo2009a</cite>. | ||

| + | |||

| + | ==== ''Back End Modules (BEM)''==== | ||

| + | |||

| + | The BEMs are composed by four identical channels each made of Low Noise Amplifiers (LNA), RF Band Pass Filter, RF to DC diode detector and DC amplifiers. | ||

| + | |||

| + | In the 30 GHz BEM, each LNA consists of two cascaded MMIC amplifiers. The Band Pass Filter is based on microstrip coupled line structure. Its design is a three order Chebyshev response band pass filter. | ||

| + | The detector is composed by a hybrid reactive/passive matching network, and a Schottky diode. A commercial Agilent beam-lead and zero-bias diode was selected. | ||

| + | The detector diode is followed by a low noise operational amplifier that provides most of the DC amplification. A second stage is implemented using an operational amplifier to provide a balanced bipolar output. | ||

| + | |||

| + | In the 44 GHz BEM, each LNA consists of self designed MMIC amplifiers manufactured with the process ED02AH from OMMIC which employs a 0.2 μm gate length Pseudomorphic-High Mobility Transistor (P-HEMT) on GaAs. | ||

| + | The topology chosen for the band-pass filter is a third order Chebyshef band pass filter made on a PTFE substrate, based on microstrip coupled line structure. | ||

| + | The detector is composed by a hybrid reactive/passive matching network and a Schottky diode. A commercial Agilent beam-lead and zero-bias diode was selected. | ||

| + | The detector diode is followed by a low noise operational amplifier that provides most of the DC amplification. A second stage is implemented using an operational amplifier to provide a balanced bipolar output. | ||

| + | |||

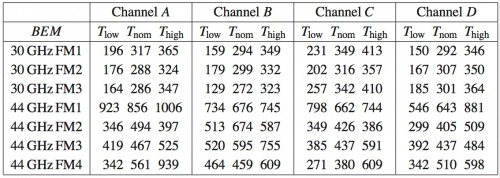

| + | Table 9 below shows the values of the equivalent noise temperature for each flight model BEM at three different temperatures in the range of possible operating temperature. The large variability of the equivalent noise temperature of 44 GHz BEM units was due to their large dependence on the input matching network result, which was observed to be a very critical parameter, not easy to control during the assembly process of MMIC. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 9. Equivalent noise temperature of the BEM Flight models in Kelvin. (One unit of each band is a Flight Spare). Estimated error: ± 20 K.''' | ||

| + | |- | ||

| + | |width="500" | [[File:bem1.jpg|thumb|center|500px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

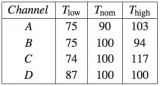

| + | The raw measurements of the output spectrum are used for the determination of the 1/f knee frequency. The results for the four channels of a 30 GHz BEM unit are given in the table below. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 10. 1/f knee frequency (Hz) of 30 GHz BEM unit.''' | ||

| + | |- | ||

| + | |width="400" | [[File:bem2.jpg|thumb|center|160px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The details of the design, development and verification of the 30 and 44 GHz back-end modules for the Planck Low Frequency Instrument can be found in <cite>#artal2009</cite>. | ||

| + | |||

| + | The 70 GHz BEM is constructed of machined aluminium with separate filter, amplifier/detector assemblies and an overall housing for other circuits and components. | ||

| + | The FEM output signals are connected by waveguide from the Focal Plane Unit (FPU) assembly to the Back End Modules (BEM’s) housed adjacent to, the Data Acquisition Electronics (DAE) assembly. To maintain compatibility with the FEM’s, each BEM will accommodate, four receiver channels, from the four, waveguide outputs of each FEM. The BEM internal signal routes are not cross coupled and can be regarded as four identical parallel circuits. | ||

| + | Each BEM is constructed as two mirror halves. The two amplifier/detector assemblies each contain two amplifier/detector circuits. Each is supplied from one of a pair of printed circuit boards which also house two DC output amplifiers. | ||

| + | |||

| + | The BEM filter characteristics hold very accurately for every channel in the six BEMs. The -3 dB pass band, 62-81 GHz, was the same in every filter within 0.5 GHz. The BEM frequency response was measured as a function of input microwave power. Also, the pass bands roll at almost exactly 63 GHz and 77 GHz. The linearity of the channel is very good as well, especially from -57 dBm upwards. The dynamic range was at least 15 dB from -57 dBm to -42 dBm. | ||

| + | In three cases, the BEMs fulfilled the power consumption requirement, while the limit was exceeded for the other three. For the total six BEMs, the limit, 3.6 W, was exceeded by approximately 140 mW. | ||

| + | Table 7 above summarises the best, the worst and the average values of the key performance parameters. The shown uncertainties are based on worst case estimates. | ||

| + | |||

| + | The details of the design, development and verification of the 70 GHz back-end modules for the Planck Low Frequency Instrument can be found in <cite>#varis2009</cite>. | ||

| + | |||

| + | ==== ''4K Load'' ==== | ||

| + | |||

| + | The purpose of the 4 K reference load is to provide the radiometer with a stable reference signal. Reducing the input offset (the radiometric temperature difference between the sky and the reference load) reduces the minimum achievable radiometer 1/f noise knee frequency for a given amplifier fluctuation spectrum. A reference load temperature that matches the sky temperature (approximately 2.7 K) would be ideal. | ||

| + | In the 4KRL design, the reference temperature is provided by the HFI outer radiation shield, at a temperature around 4K. | ||

| + | The 4KRL performance are reported in Table 11 below. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 11. RF measured performance for the 4KRL: RH (+WaveGuide) Insertion Loss, RH (+WG) RL, RH (+WG) + RT Return Loss. 70 GHz performance have been measured using a representative Reference Horn and waveguide, since RHs are internal to FEMs: this value is reported in the table. RCAs 24-26 are the LFI 44 GHz channels, 27 and 28 the 30 GHz ones. M and S refer to Main and Side OMT arm, respectively. | ||

| + | <math>∗</math> Measured on the FM RTs and a representative Reference Horn.''' | ||

| + | |- | ||

| + | |width="600" | [[File:4krl.jpg|thumb|center|300px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

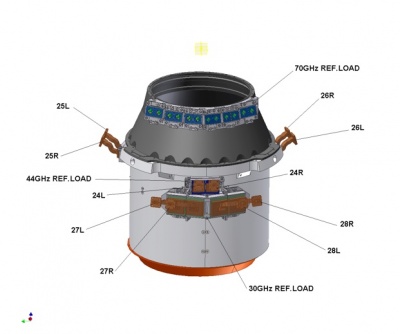

| + | The 4K reference load unit is formed by single targets, one for each radiometer (two for each FEM). The horns used to couple to the 4 K reference load targets need to be relatively small because the targets themselves are small. An optimisation process produced a different horn design for each LFI band: their dimensions increase with reducing frequency. Due to the LFI Focal Plane design, where higher frequency radiometers (70 GHz) are placed around the HFI cryostat and the lower frequency radiometers (30 and 44 GHz) in a second row, the target mounting structure is separated in two parts, see Figure 5 below. | ||

| + | The upper one is located around the conical part of the HFI outer shield. Reference targets are mounted on a supporting structure, thermally and mechanically connected to the HFI outer shield. Each target faces a reference horn, two for each FEM. This ensemble is fixed to a support structure on the HFI 4K shield. Thermal link between the mounting structure and the HFI is obtained via fixation point only. Thermal washers are interposed to damp temperature fluctuations on targets induced by the HFI outer shield temperature oscillations. | ||

| + | The lower part is fixed in the cylindrical part. It is made with the same target geometry of the upper part, and it is fixed on the HFI shield. The reference horns face the loads and are connected to the FEMs through WGs. | ||

| + | Reference WGs and RH (Reference Horns) are either included in the FEM (70 GHz) or external to FEM (30 and 44 | ||

| + | GHz). | ||

| + | |||

| + | [[File:4kload.jpg|thumb|center|400px|Figure 5. 4K reference load targets mounted on the HFI 4K shield]] | ||

| + | |||

| + | Targets are formed of a back section, made of ECCOSORB CR117, which shows higher RF absorption but also high reflectivity. To reduce the target global reflectivity, a front section, assembled with an ECCOSORB specific cement to the back one, faces the radiometer Reference Horn. This last is casted from ECCOSORB CR110, whose RF reflectivity is lower than that of CR117. Target design is optimised to further reduce both reflectivity and leakage. Each target is metal backed and it is mounted in a metal enclosure. | ||

| + | |||

| + | Thermal tests were performed in the IASF-Bo 4K cryo facility, equipped with a GM cooler, with an heat lift up to 1.5 W at 4K. The setup simulated the real environment in the payload, where targets are mounted on the HFI 4K shield in front of the quasi-cylindrical LFI main frame at about 20 K. It was also used to test the susceptibility to fluctuations of the LFI. | ||

| + | |||

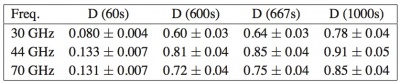

| + | The thermo-mechanical damping was evaluated from the transient test, inducing sinusoidal temperature fluctuation with periods of 60, 600, 667 (typical Sorption Cooler period) and 1000 seconds at the level of the attachment point of the loads on the support structures. The fluctuation at the level of the targets is then acquired and the transfer function (amplitude and phase) are estimated by the ratio of the amplitudes. The final results are summarized in the table 12. | ||

| + | |||

| + | {| border="0" cellspacing="0" cellpadding="2" align="center" | ||

| + | |+ '''Table 12. Thermal fluctuation damping measured for the reference loads at different frequencies.''' | ||

| + | |- | ||

| + | |width="800" | [[File:4krl_t.jpg|thumb|center|400px|]] | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | Details of the design and performance of the LFI 4K reference load units are given in <cite>#valenziano2009</cite>. | ||

| + | |||

| + | == References == | ||

| + | |||

| + | |||

| + | <biblio force=false> | ||

| + | #[[References]] | ||

| + | </biblio> | ||

Revision as of 12:47, 21 February 2013

Contents

Appendix: LFI Instrument[edit]

Feed Horns (FH)[edit]

Dual profiled corrugated horns have been selected at all LFI frequencies as the best design in terms of shape of the main lobe, level of the side lobes, control of the phase centre, and compactness. Dual profiled LFI horns are composed by a Sine Squared profiled section, and an exponential profile near the aperture plane. In order to optimise the optical matching of the feeds phase centres to the telescope focal surface, while preventing obscuration between horns, LFI has 6 different feed horn designs. For each frequency, the number of feeds and the number of different designs are reported in Table 1 below.

| Frequency (GHz) | Number of Horns | Number of designs |

|---|---|---|

| 30 | 2 | 1 |

| 44 | 3 | 2 |

| 70 | 6 | 3 |

LFI feed horn design specifications are reported in the table 2 below.

The design process led to a corrugation profile composed by a mixture of a sine-squared section, starting from the throat, and an exponential section near the aperture plane. The length of this last has a direct impact on the location of the phase center. The analytical expression of the corrugation profile, , is the following

in the sine section, and

in the exponential region. Here, is the throat radius, is the sine squared region end radius (or exponential region initial radius), is the aperture radius, is the sine squared region length and is the exponential region length. The parameter modulates the first region profile between linear and pure sine squared type. The parameters , and can be used to control, as far as possible, the position and frequency stability of the phase center and the compactness of the structure. The feed horn parameters are reported in table 3 below.

The qualification campaign, mainly focused on RF return loss and pattern (amplitude and phase) measurements, was successfully concluded. The agreement between the pattern measurements and the expected performances (simulated using nominal corrugation profile) is excellent both in amplitude and in phase. Moreover reflection measurements show a good impedance match for all the horns, the return loss being better than -30 dB over the whole 20% of operational bandwidth.

Details of the design, flight model and tests of Planck-LFI feed horns can be found in #villa2009.

OrthoMode Transducers (OMT)[edit]

The Ortho–Mode Transducer (OMTs) separates the radiation collected by the feed horn in two orthogonal polarisation components. It consists of a circular to square waveguide transition (directly connected to the FH), a square waveguide section and two separate rectangular waveguide (the through and side arms, which separate and pick up the orthogonal polarisation, connected with the FEU). On the side arms is always present a 90 degrees bend, while a twist is also necessary on the main (30 and 44 GHz) and side (70GHz) arm, in order to math the FEU polarisation.

The required and measured performances for the LFI OMTs at all frequencies are reported in the following tables 4 and 5:

| OMT ID | Bandwidth [GHz] | X–Pol [dB] (Main) | X–Pol [dB] (Side) | Return–Loss [dB] (Main) | Return–Loss [dB] (Side) |

|---|---|---|---|---|---|

| 18 | 14 | <29 | <30 | -15.0 | -20.0 |

| 19 | 14 | <26 | <28 | -15.0 | -20.0 |

| 20 | 14 | <32 | <35 | -15.0 | -20.0 |

| 21 | 14 | <32 | <37 | -15.0 | -18.0 |

| 22 | 14 | <26 | <28 | -15.0 | -18.0 |

| 23 | 14 | <26 | <28 | -15.0 | -20.0 |

| 24 | 8.8 | <38 | <40 | -13.0 | -18.0 |

| 25 | 8.8 | <31 | <32 | -13.0 | -18.0 |

| 26 | 8.8 | <27 | <25 | -13.0 | -17.0 |

| 27 | 6 | <38 | <44 | -16.0 | -23.0 |

| 28 | 6 | <36 | <38 | -16.0 | -22.0 |

The details of the flight models and measurements of the Planck LFI ortho-mode transducers can be found in #darcangelo2009b.

Front End Modules (FEM)[edit]

Front End Modules are located in the FPU, just in cascade of the Feed Horn and the Ortho Mode Transducers. 70 GHz FEMs are mounted onto the inner wall of the mainframe (the wall facing HFI instrument) from the HFI side. 44 and 30 GHz FEMs are inserted into the mainframe from the WG side and fixed to the bottom plate. Screws to bottom plate are inserted from WG side. The LFI FEMs are the first active stage of amplification of the radiometer chain. Each FEM contains four amplification paths. Each path is composed by several cascaded LNAs followed by a phase switch. Two passive hybrids, at the input and output of the FEM, are used to mix couples of signals of the same radiometer (see Figure 4). This makes the instabilities of each chain to be applied to both the sky and load signals.

The passive hybrid coupler (magic-tee) combines the signals from the sky and cold load with a fixed phase offset of either 90 deg or 180 deg between them. It has a 20% bandwidth, low loss, and amplitude balance needed at the output to ensure adequate signal isolation.

The FEM LNAs (InP MMIC) are biased providing 1 drain line per channel (that is 4 per FEM) and 2 gate lines per channel (that is 8 per FEM). The FEM Phase switches are biased providing 2 lines per channel (that is 8 per FEM) each capable of providing a direct bias current or a reverse bias voltage.

The LFI FEM parameters necessary to meet the science objectives at 30 and 44 GHz were given as requirements and goals and are summarised in table 6 below where they are compared with the values actually achieved. The FEM units meet the requirements, within the measurement errors, for most parameters and in particular the noise temperature. The units come close to the more stringent goals in several parameters. Of particular note are the noise temperatures achieved; these along with the wide bandwidths are critical for the high sensitivity required for the Planck mission. Some LNAs within the FEMs met the goals at 30 GHz and 44 GHz within the measurements errors and reached 3 and 5 times the theoretical quantum limit respectively at the band centres. Furthermore, a range of tests showed that LNAs and FEMs achieved the stability levels required to meet the observing strategy of Planck. In particular, the 1/f noise knee frequency ≤29 mHz, close to the goal, met the conditions imposed by the 60 second rotation period of the spacecraft. The linear polarization performance of the FEMs exceeded the requirements of the mission. The isolation between the E- and H- polarizations was measured to be between 51 and 58 dBs for the various FEMs. The LFI radiometers have very well determined position angle precision, being determined by the accuracy of the waveguide engineering. The 30 and 44 GHz geometry is accurate to ∼ ; the corresponding precision is ∼ in the HFI polarimeters. The temperature stability requirement values are also given in the table 6 below.

The details of the design, development and verification of the 30 and 44 GHz front-end modules for the Planck Low Frequency Instrument can be found in #davis2009.

For what regards the 70 GHz channels, for the LNA selection of the FEMs, nine different wafers from various processing runs were evaluated, only the LNAs with the best performance were assembled as the first stage amplifiers in the FEM ACAs. For the phase switch selection, four different wafers were evaluated. When the signal is passed to an output, the gain is 35 dB or higher for almost the entire required range, and on average, the Planck requirement was fulfilled. In all FEMs, the average channel gains ranged from 34.0-40.0 dB (uncertainty ±0.1 dB). When the signal is isolated from an output, the gain is 20 dB lower or more at all frequencies. This difference in gain is used as the measure for isolation. In all the six FEMs, the channel isolation values ranged from 11.3-22.1 dB (uncertainty ±0.1 dB).

Table 7 below summarises the best, the worst and the average values of the key performance parameters. The shown uncertainties are based on worst case estimates.

The details of the design, development and verification of the 70 GHz front-end modules for the Planck Low Frequency Instrument can be found in #varis2009.

Waveguides[edit]

The LFI Front End Unit (FEU) is connected to the Back End Unit (BEU) by 44 rectangular waveguides approximately 1.5-2.0 meter long. Each waveguide exhibits low VSWR, low thermal conductivity, low insertion loss, and low mass. In addition, the waveguide path shall permit the LFI/HFI integration and the electrical bonding between FPU and BEU. Because of the Focal Plane Unit arrangement, the waveguides are in general twisted and bended in different planes and with different angles, depending on the particular waveguide. From the thermal point of view the waveguides have to connect 2 systems (BEM and FEM) that are at very different temperatures. At BEM level the waveguides are at a temperature of 300K while at FEM level the temperature is 20K. The waveguides have to reduce the thermal flow from 300K to 20K. In Figure 1 (left panel) a conceptual sketch of the LFI configuration is shown.

All the required characteristics cannot be realized with single material waveguide configuration; a composite waveguide configuration is needed. The WGs can be considered divided in three sections: 1. 400 mm of Stainless Steel (gold plated) straight waveguide section, attached to the BEU, ending after the 3rd V–groove; 2. 300 mm of non–plated Stainless Steel (SS). The SS-sections are identical for all the channels except for internal dimensions, depending on frequency. These guides are connected to all the V-grooves in order to dissipate the heat produced at BEU level. 3. bended and twisted 400 microns thin electroformed copper waveguide starting at the end of the SS–section and attached to the FEU, whose length varying from around 800 mm to 1300 mm, with 2 to 4 Cu-joints. The copper waveguides section is connected to a mechanical support structure in five points in order to increase the stiffness of the waveguide.

The performance for the LFI waveguides at all frequencies are reported in the following table 8:

| Frequency | band [GHz] | Number | IL [dB] @20 K | RL [dB] | Isolation [dB] | R [mΩ] @20 K | R [mΩ] @300 K |

|---|---|---|---|---|---|---|---|

| 30 | 27-33 | 8 | <2.5 (1.0) | <-25 | <-30 | 11.8 | 27.3 |

| 44 | 39.6-48.4 | 12 | <3.0 (1.5) | <-25 | <-30 | 14.7 | 34.1 |

| 70 | 63-77 | 24 | <5.0 (3.5) | <-25 | <-30 | 26.2 | 60.5 |

From the thermal point of view the waveguides have to connect 2 systems (BEM and FEM) that are at different temperatures. At BEM level the waveguides are at a temperature of 300K while at FEM level the temperature is 20K. Along the Stainless Steel section the waveguides have to reduce the thermal flow from 300K to 20K. The Stainless Steel waveguide is connected to all the V-grooves in order to dissipate the heat produced at BEU level.

Details of the Planck-LFI flight model of the composite waveguides can be found in #darcangelo2009a.

Back End Modules (BEM)[edit]

The BEMs are composed by four identical channels each made of Low Noise Amplifiers (LNA), RF Band Pass Filter, RF to DC diode detector and DC amplifiers.

In the 30 GHz BEM, each LNA consists of two cascaded MMIC amplifiers. The Band Pass Filter is based on microstrip coupled line structure. Its design is a three order Chebyshev response band pass filter. The detector is composed by a hybrid reactive/passive matching network, and a Schottky diode. A commercial Agilent beam-lead and zero-bias diode was selected. The detector diode is followed by a low noise operational amplifier that provides most of the DC amplification. A second stage is implemented using an operational amplifier to provide a balanced bipolar output.

In the 44 GHz BEM, each LNA consists of self designed MMIC amplifiers manufactured with the process ED02AH from OMMIC which employs a 0.2 μm gate length Pseudomorphic-High Mobility Transistor (P-HEMT) on GaAs. The topology chosen for the band-pass filter is a third order Chebyshef band pass filter made on a PTFE substrate, based on microstrip coupled line structure. The detector is composed by a hybrid reactive/passive matching network and a Schottky diode. A commercial Agilent beam-lead and zero-bias diode was selected. The detector diode is followed by a low noise operational amplifier that provides most of the DC amplification. A second stage is implemented using an operational amplifier to provide a balanced bipolar output.

Table 9 below shows the values of the equivalent noise temperature for each flight model BEM at three different temperatures in the range of possible operating temperature. The large variability of the equivalent noise temperature of 44 GHz BEM units was due to their large dependence on the input matching network result, which was observed to be a very critical parameter, not easy to control during the assembly process of MMIC.

The raw measurements of the output spectrum are used for the determination of the 1/f knee frequency. The results for the four channels of a 30 GHz BEM unit are given in the table below.

The details of the design, development and verification of the 30 and 44 GHz back-end modules for the Planck Low Frequency Instrument can be found in #artal2009.

The 70 GHz BEM is constructed of machined aluminium with separate filter, amplifier/detector assemblies and an overall housing for other circuits and components. The FEM output signals are connected by waveguide from the Focal Plane Unit (FPU) assembly to the Back End Modules (BEM’s) housed adjacent to, the Data Acquisition Electronics (DAE) assembly. To maintain compatibility with the FEM’s, each BEM will accommodate, four receiver channels, from the four, waveguide outputs of each FEM. The BEM internal signal routes are not cross coupled and can be regarded as four identical parallel circuits. Each BEM is constructed as two mirror halves. The two amplifier/detector assemblies each contain two amplifier/detector circuits. Each is supplied from one of a pair of printed circuit boards which also house two DC output amplifiers.

The BEM filter characteristics hold very accurately for every channel in the six BEMs. The -3 dB pass band, 62-81 GHz, was the same in every filter within 0.5 GHz. The BEM frequency response was measured as a function of input microwave power. Also, the pass bands roll at almost exactly 63 GHz and 77 GHz. The linearity of the channel is very good as well, especially from -57 dBm upwards. The dynamic range was at least 15 dB from -57 dBm to -42 dBm. In three cases, the BEMs fulfilled the power consumption requirement, while the limit was exceeded for the other three. For the total six BEMs, the limit, 3.6 W, was exceeded by approximately 140 mW. Table 7 above summarises the best, the worst and the average values of the key performance parameters. The shown uncertainties are based on worst case estimates.

The details of the design, development and verification of the 70 GHz back-end modules for the Planck Low Frequency Instrument can be found in #varis2009.

4K Load[edit]

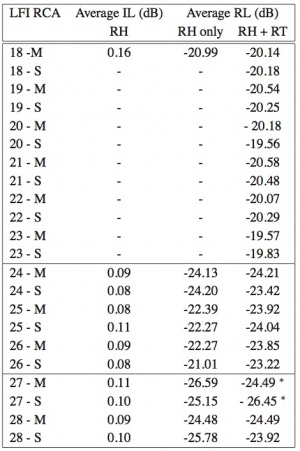

The purpose of the 4 K reference load is to provide the radiometer with a stable reference signal. Reducing the input offset (the radiometric temperature difference between the sky and the reference load) reduces the minimum achievable radiometer 1/f noise knee frequency for a given amplifier fluctuation spectrum. A reference load temperature that matches the sky temperature (approximately 2.7 K) would be ideal. In the 4KRL design, the reference temperature is provided by the HFI outer radiation shield, at a temperature around 4K. The 4KRL performance are reported in Table 11 below.

The 4K reference load unit is formed by single targets, one for each radiometer (two for each FEM). The horns used to couple to the 4 K reference load targets need to be relatively small because the targets themselves are small. An optimisation process produced a different horn design for each LFI band: their dimensions increase with reducing frequency. Due to the LFI Focal Plane design, where higher frequency radiometers (70 GHz) are placed around the HFI cryostat and the lower frequency radiometers (30 and 44 GHz) in a second row, the target mounting structure is separated in two parts, see Figure 5 below. The upper one is located around the conical part of the HFI outer shield. Reference targets are mounted on a supporting structure, thermally and mechanically connected to the HFI outer shield. Each target faces a reference horn, two for each FEM. This ensemble is fixed to a support structure on the HFI 4K shield. Thermal link between the mounting structure and the HFI is obtained via fixation point only. Thermal washers are interposed to damp temperature fluctuations on targets induced by the HFI outer shield temperature oscillations. The lower part is fixed in the cylindrical part. It is made with the same target geometry of the upper part, and it is fixed on the HFI shield. The reference horns face the loads and are connected to the FEMs through WGs. Reference WGs and RH (Reference Horns) are either included in the FEM (70 GHz) or external to FEM (30 and 44 GHz).

Targets are formed of a back section, made of ECCOSORB CR117, which shows higher RF absorption but also high reflectivity. To reduce the target global reflectivity, a front section, assembled with an ECCOSORB specific cement to the back one, faces the radiometer Reference Horn. This last is casted from ECCOSORB CR110, whose RF reflectivity is lower than that of CR117. Target design is optimised to further reduce both reflectivity and leakage. Each target is metal backed and it is mounted in a metal enclosure.

Thermal tests were performed in the IASF-Bo 4K cryo facility, equipped with a GM cooler, with an heat lift up to 1.5 W at 4K. The setup simulated the real environment in the payload, where targets are mounted on the HFI 4K shield in front of the quasi-cylindrical LFI main frame at about 20 K. It was also used to test the susceptibility to fluctuations of the LFI.

The thermo-mechanical damping was evaluated from the transient test, inducing sinusoidal temperature fluctuation with periods of 60, 600, 667 (typical Sorption Cooler period) and 1000 seconds at the level of the attachment point of the loads on the support structures. The fluctuation at the level of the targets is then acquired and the transfer function (amplitude and phase) are estimated by the ratio of the amplitudes. The final results are summarized in the table 12.

Details of the design and performance of the LFI 4K reference load units are given in #valenziano2009.

References[edit]

<biblio force=false>

</biblio>

(Planck) Low Frequency Instrument

Feed Horn

LFI Ortho Module Transducer

LFI cryogenic amplifying stage Front End Unit

LFI cryogenic amplifying stage Front End Module

Focal Plane Unit

(Planck) High Frequency Instrument

LFI Waveguide

LFI warm electronics Back End Unit

LFI warm electronics Back End Module

High Electron Mobility Transistor

LFI Data Acquisition Electronics